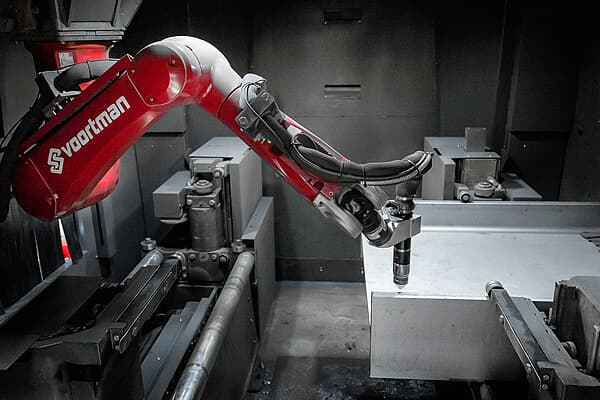

Robotic Coping Machine Assembly

Voortman�s V808 robotic heating cutting machine, like all others, comes with the VACAM software. This allows all machines to speak the same "language". The V808 has a lot of versatility and can be used either as a part of a new layout that includes roller conveyors, cross-transports, and other Voortman processing machines or as a standalone center.

All types of shapes and layout markings on all four sides can be done by the V808 robotic profile processor. It is capable of producing profiles up to 1.250mm (50") wide. Our Voortman V807 robot can handle profiles up to 1.050mm (42") if this width is not required. The V808 can thermally process rat holes, slotted web and "dogbone" cuts, copes at the beginning or end of products, block outs, holes of all sizes and shapes, weld preparations, marking on all four sides, and many other types of cuts.